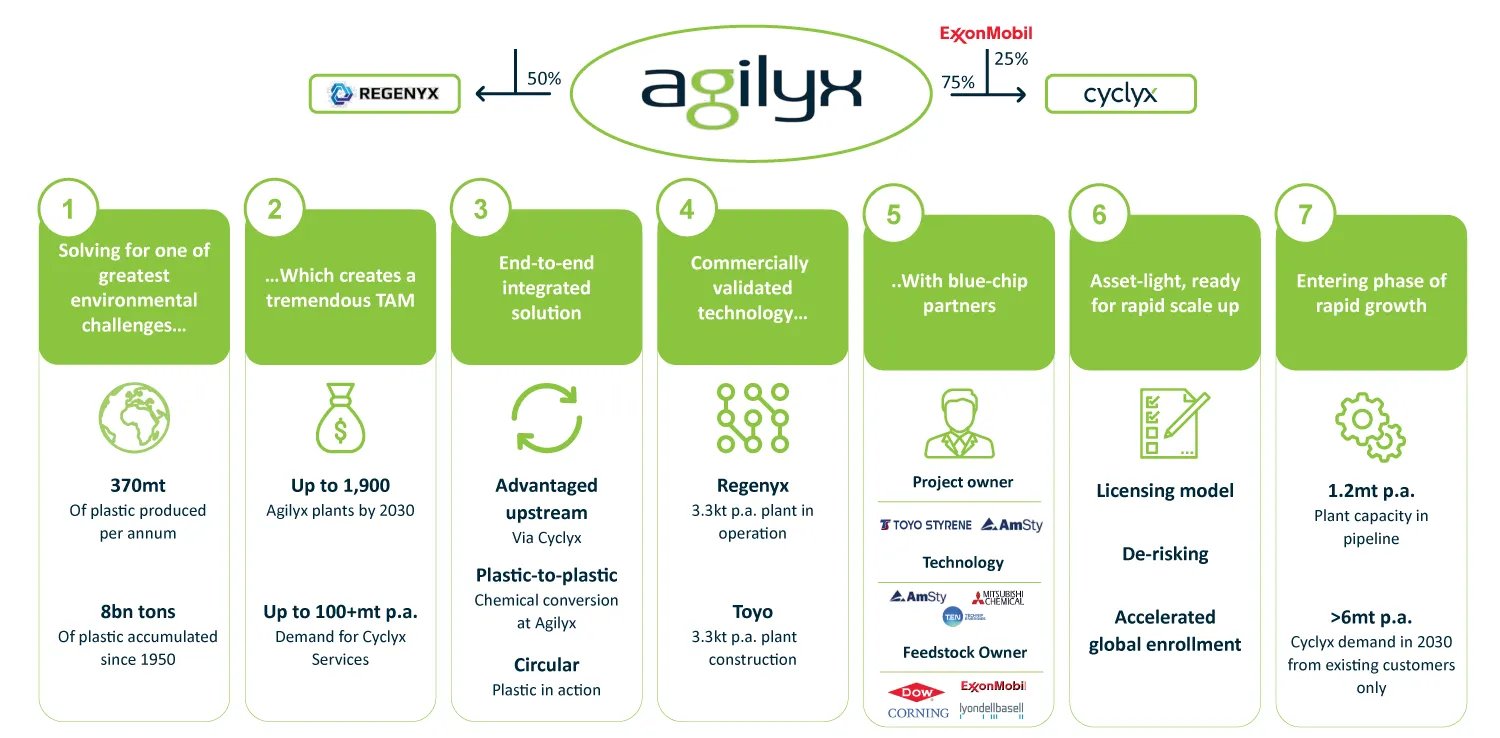

Agilyx, founded in 2004, is a leader in chemical plastics recycling solutions, positioned to solve and mitigate the global challenge of plastic waste. The company has developed a patented, flexible, commercially validated and scalable solution to convert waste plastic into recycled materials and products in a massive yet untapped market. With Cyclyx, a JV with ExxonMobil, Agilyx possesses the industry know-how of feedstock supply and management. Being a technology enabler that deploys an asset light model, Agilyx can scale many projects simultaneously and rapidly. ExxonMobil, Virgin, Mitsubishi Chemical and Technip Energies are several selected key partners of the company.

OTCQX: AGXXF

OSE: AGLX

IR Website: agilyx.com/investors

OTC Markets Profile: otcmarkets.com/stock/AGXXF/overview

Headquarters: Portsmouth, New Hampshire

TALK TO MANAGEMENT

Agilyx is always available to talk to current and potential investors. They're happy to answer any questions you may have and tell you what makes their story unique. Please fill out this form, and we will connect you shortly.

All content on this page is accurate as of 06.08.23.

Agilyx At A Glance

Agilyx, founded in 2004, is a leader in chemical plastics recycling solutions, positioned to solve and mitigate the global challenge of plastic waste. The company has developed a patented, flexible, commercially validated, and scalable solution to convert waste plastic into recycled materials and products in a massive yet untapped market. With Cyclyx, a JV with ExxonMobil, Agilyx possesses the industry know-how of feedstock supply and management. Being a technology enabler that deploys an asset light model, Agilyx can scale many projects simultaneously and rapidly. ExxonMobil, Virgin & Technip Energies are several selected key partners of the company.

Key Considerations:

Press Releases & Media Coverage

Newpark announced as the newest Cyclyx consortium member

BioBTX and Agilyx announce collaboration for the production of circular aromatic chemicals

Agilyx and INEOS Styrolution advance development of large scale TruStyrenyx™ plant

Evergreen announced as the newest member of the Cyclyx consortium

HISD receives $300,000 in support of its new recycling program

Supply Chain Company Savage Reduces Plastic Waste

Savage Joins Cyclyx 10 to 90® Program to Help Reduce Plastic Waste

JANUARY 24, 2023

Agilyx CEO, Tim Stedman, named among the ICIS Top 40 Power Players in 2023

Agilyx Appoints Marie Conrad Vice President of Business Development, North America

JANUARY 9, 2023

OTC Markets Group Welcomes Agilyx AS to OTCQX

Staying on Top of the Curbside Holiday Load

Investor Presentation

To download the Agilyx Corp. investor presentation, please fill out the form below.

Agilyx Value Proposition

Solving the Global Plastic Waste Environmental Challenges

Plastic is arguably one of the most significant human inventions of the past century and has transformed modern life, yet its useful life is short, most of it is discarded after a single use, and the waste created has caused massive environmental concern and threatens our planet well into the future.

Source: Companies’ data, OECD, ResearchGate, UN Environmental Programme, public sources

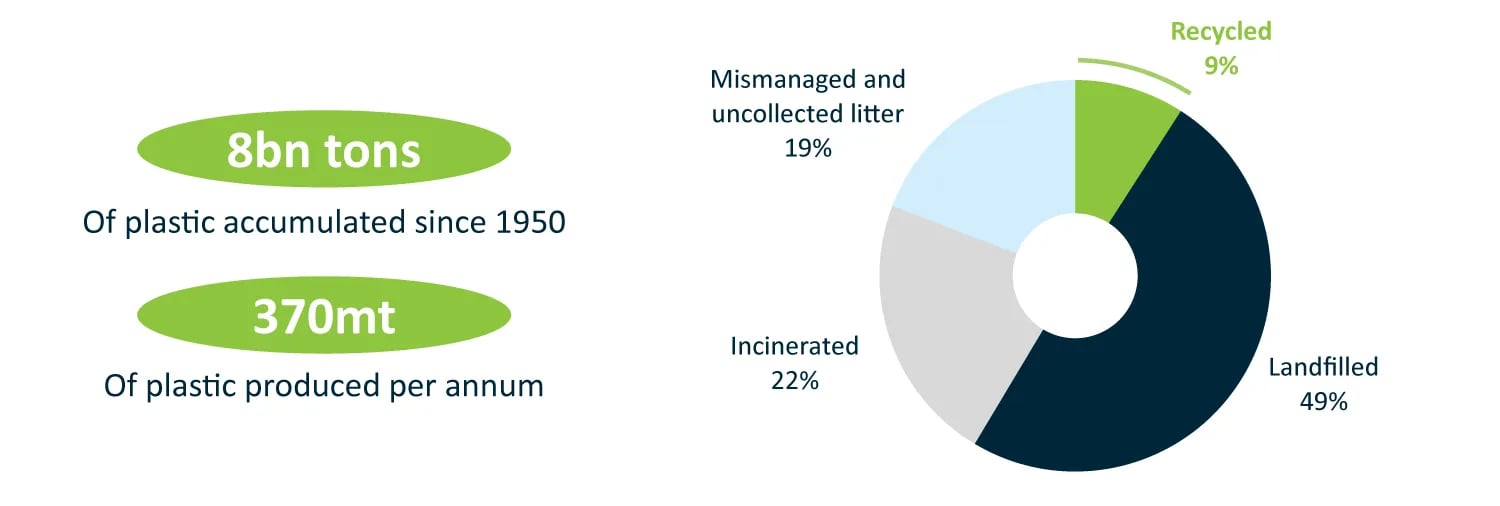

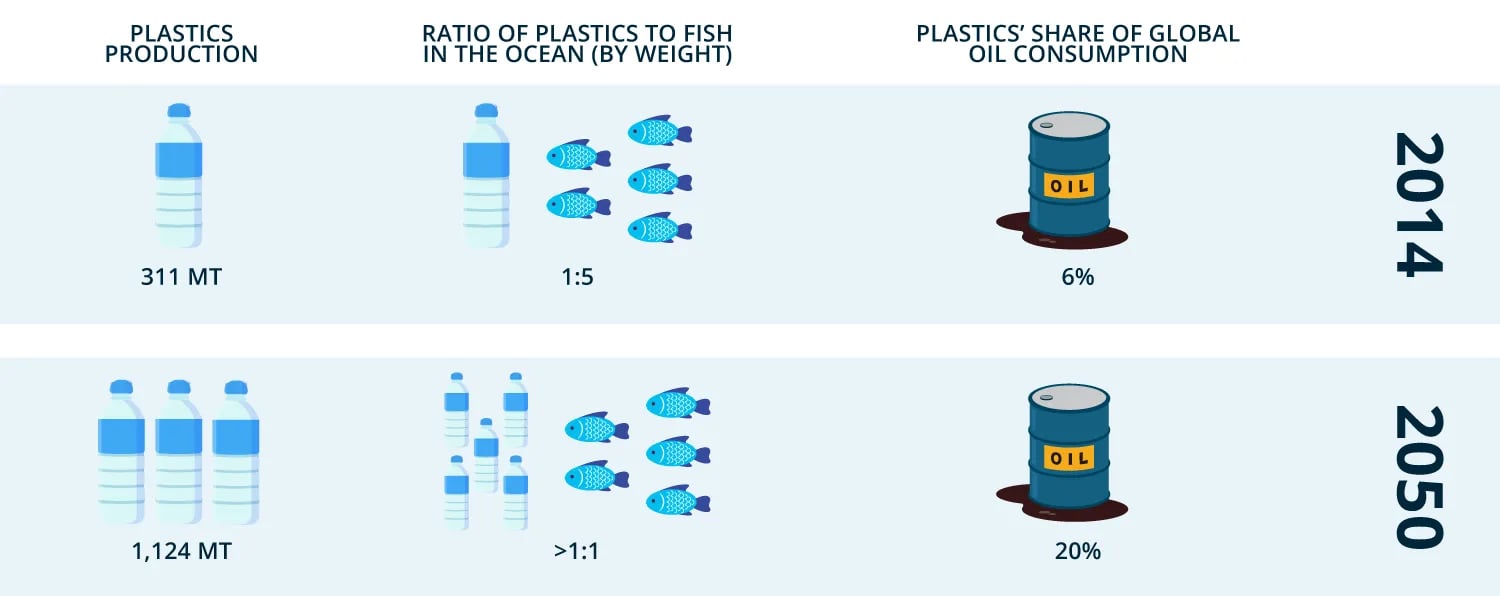

On a global basis, we have accumulated 8 billion tons of plastics since 1950, and each year another 370 metric tons are produced with only 9% of them being recycled. The rest were placed into landfills, incinerated, and/or leaked or mismanaged, thus harming animal life, clogging drains, and infiltrating food chains and waters. If nothing is done, some estimate there will be more plastic than fish in the ocean by 2050.

In addition, 90% of feedstock for plastics is derived from fossil fuel usage, representing 6% of total oil consumption today, and an estimated 20% by 2050, predicted by IEA. As a result, excess emissions is one issue. Single use plastics have also resulted in significant amounts of value being lost or trapped underground following just a short first-use cycle.

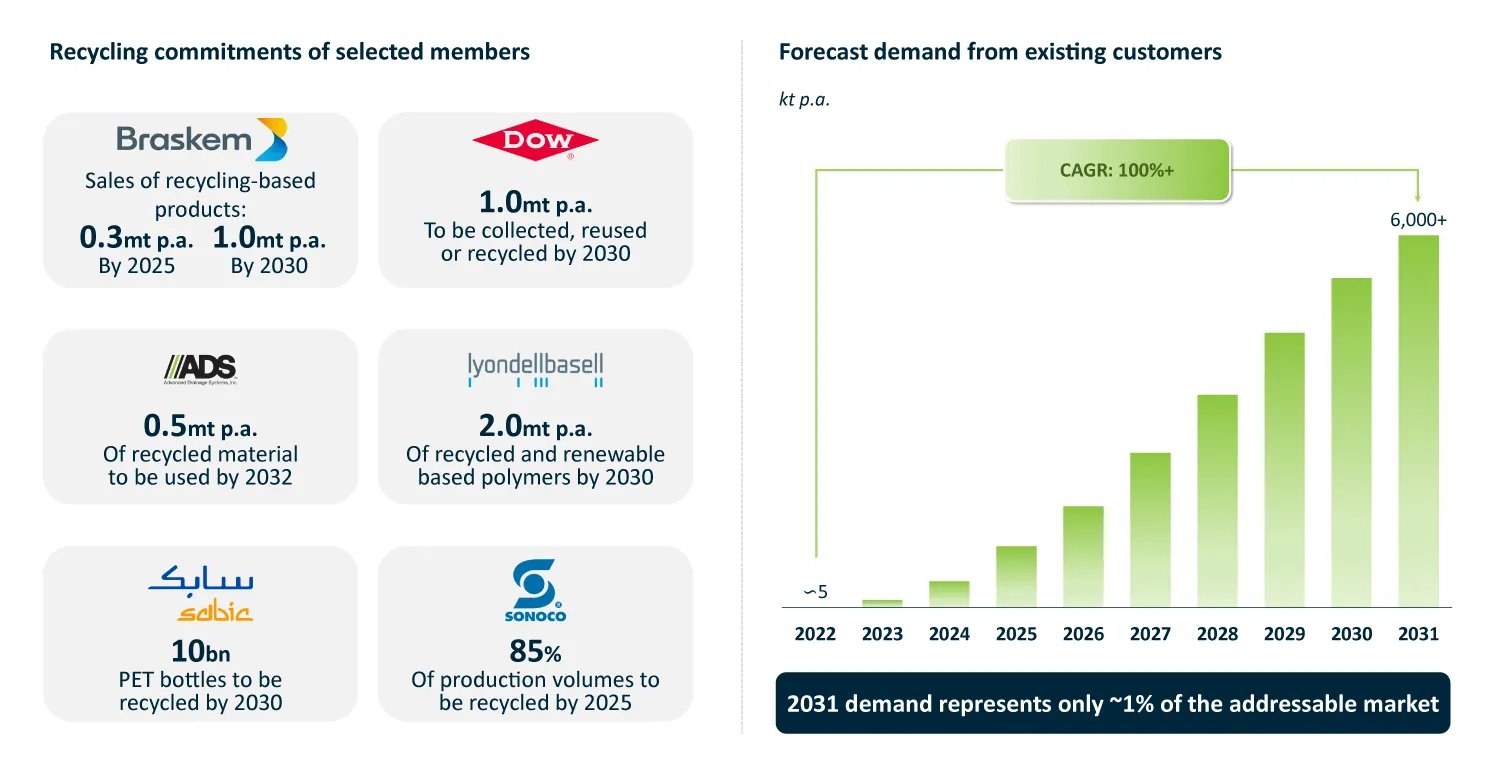

Recycling is largely considered a key solution to plastic waste, with the EU leading the global effort by setting ambitious targets such as 50% of plastic packaging needing to be recycled by 2025, and an 800 euro tax levy imposed for each ton of non-recycled plastic waste. The Recovery Act in the U.S. calls for a $500 million grant for recycling infrastructure. The industry also gets noticeable buy-ins from leading global brands, as plenty of them have made significant recycling commitments concerning their plastic content (mostly packaging).

Source: Companies’ data, OECD, ResearchGate, UN Environmental Programme, public sources.

Chemical Recycling Makes Plastic a Circular Resource

Today, an overwhelming majority of the 9-10% of plastic being recycled is done by mechanical recycling which involves shredding, grinding, and melting. However, mechanical recycling as it stands today damages the structure of the plastic chains, resulting in it only being able to be recycled one to two times. The output is also generally not suitable for food and medical applications.

Agilyx has been recycling plastic waste since 2014, and along with mechanical recycling is a leader in chemical recycling, utilizing all available options to promote a circular economy.

Chemical recycling refers to the chemical processing of converting waste plastic into virgin raw materials. It addresses many mechanical shortcomings given its high tolerance to contamination, usability of high-quality end products, flexible treatment of mixed plastic waste, and wide range of inputs.

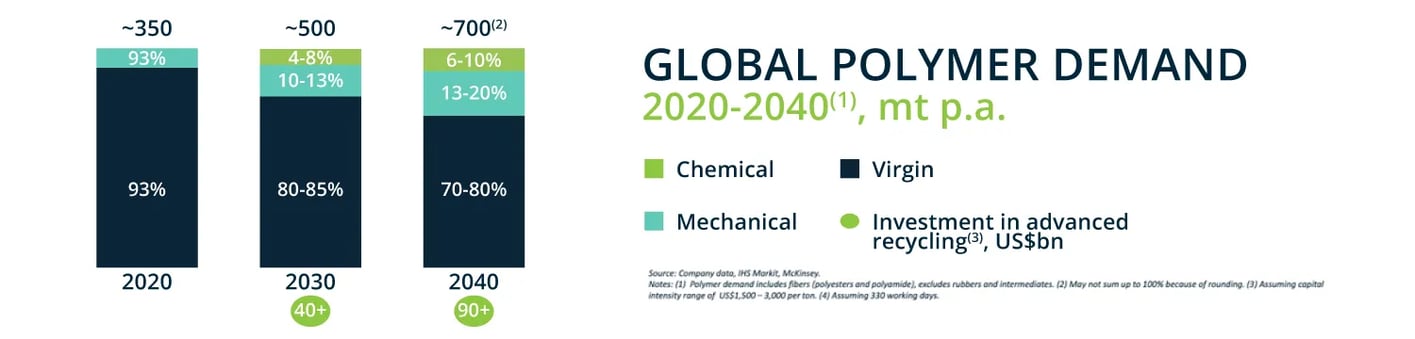

While mechanical recycling will remain a key process in the future, chemical recycling (see diagram above) will likely take off and cover a sizable portion of plastic demand by 2030 and further advance well into 2040. Investments in chemical recycling will increase to $40 billion by 2030 and $90 billion by 2040, from a significantly lower level today.

BioBTX: A New Waste-to-Product Pathway

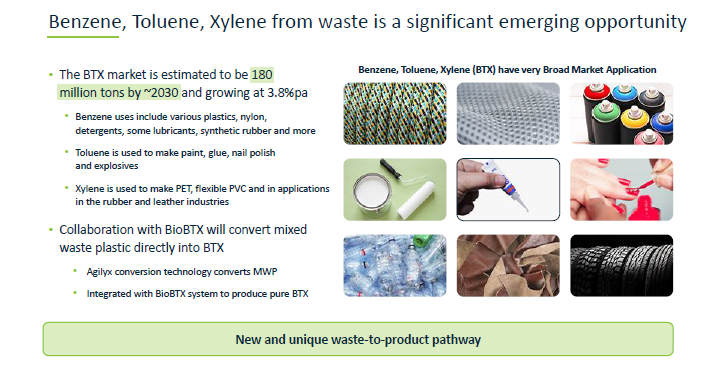

Aromatic chemicals (BTX) such as benzene, toluene and xylene are key chemical building blocks, representing 40% of the petrochemicals in terms of volume. However, these chemicals are highly toxic and not easily disposed of, and as such Agilyx sensed a significant market opportunity.

As such, Agilyx recently entered into a strategic collaboration with BioBTX B.V. (“BioBTX”), the global leader in renewable aromatics technology to explore the scale-up of BioBTX technology at a commercial demonstration plant for the production of renewable aromatic chemicals (benzene, toluene, xylene: BTX).

The partnership will bring Agilyx technology into BioBTX’s first commercial plant. Agilyx’s pyrolysis technology for difficult-to-recycle post-use plastics combined with BioBTX catalytic technology to convert pyrolysis vapours into aromatic chemicals will create a unique synergy for the production of renewable aromatic chemicals (BTX).

The integration of these two technologies will yield a high quality BTX product, meeting the demanding specifications of the chemical industry whilst also converting difficult to recycle plastic waste streams.

A Sizable Addressable Market

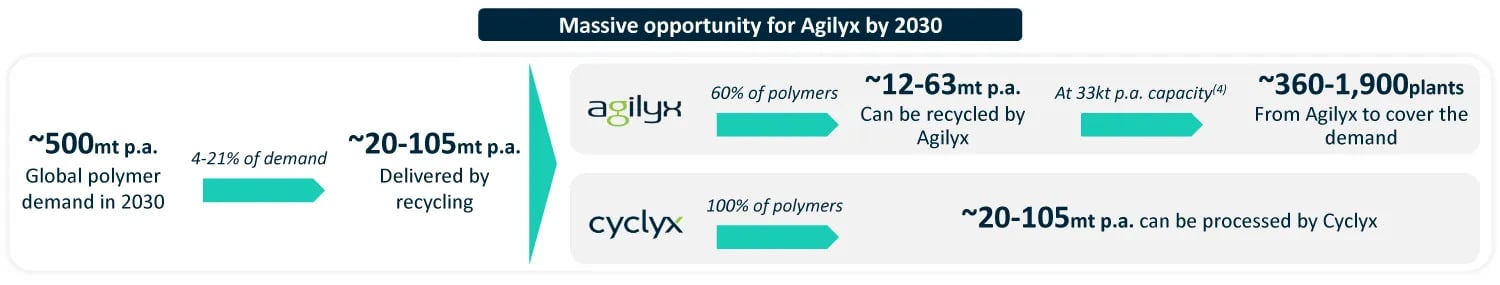

The total addressable market is about $12 billion to $67 billion in size* (360-1900 conversion plants, and 20-105 metric tons per annum in feedstock supply and management). Agilyx earns revenue by licensing its technology to plastics conversion and waste processing plants and earns royalty revenue based on volume of feedstock processed through Cyclyx and Agilyx enabled facilities.

Out of the 5 major types of plastics, Agilyx can recycle 60% of those polymers in the current market.

It is estimated the global demand for plastics (polymers) will reach ~500 mt a year by 2030, from 370 today. Of that 500 mt, assuming 4-21% will be made from recycling waste plastics, that translates to ~20-105 mt. As illustrated by the previous diagram, Agilyx can recycle 60% of polymers today, translating into ~12-63 mt a year. At a 33k per year capacity, that means there are between 360-1900 plants that Agilyx can license its technology to to enable the recycling process. In addition, Cyclyx ( the 75% feedstock supply and management JV) can cover the entire plastics universe and can manage and supply 20-105 mt per year in feedstock to plastic makers.

*Agilyx data - The addressable market size value is calculated based on the estimates that each plant that has a 33kt pa output will generate about $35 million of cash flow in recurring royalties and services during the operation phase.

Video: The Plastic Recycling Revolution

An End-to-End Solution w/ Feedstock management as an Advantage

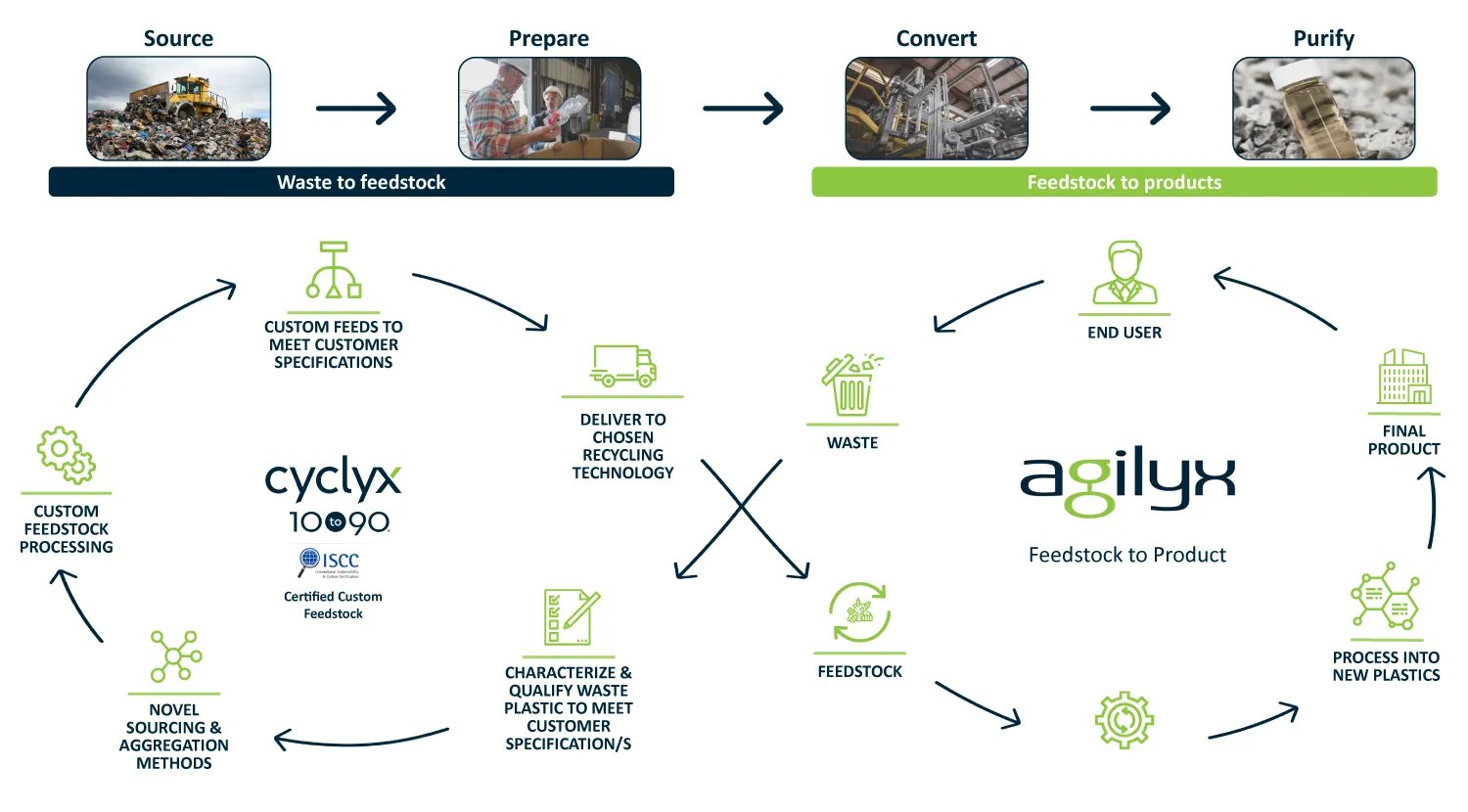

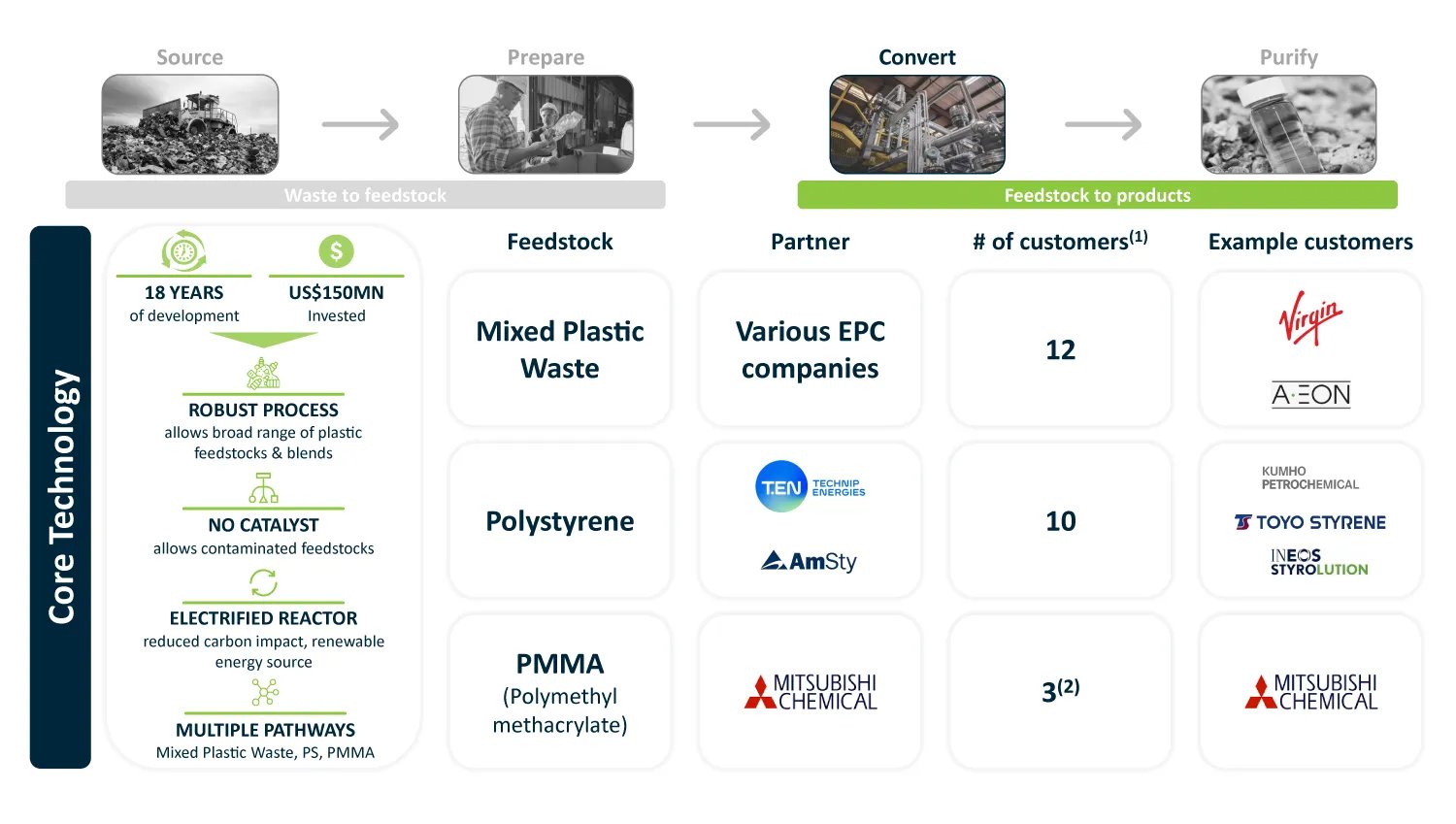

There are four steps needed to deliver chemically recycled plastic: Source, Prepare, Convert and Purify

Waste to Feedstock Enablement

The process begins with Cyclyx which sources plastic waste and prepares it into ready-to-recycle feedstock for downstream recycling process.

What makes Cyclyx unique is its ability to leverage probably the most comprehensive chemical conversion database for chemical characterization of waste plastics, which then allows for the development of custom feedstock recipes based on the demand of the recycled end products and customer process specifications. This is a more advanced approach compared to the conventional method where stakeholders decide on what recycled end products to make based on what plastic waste is available.

Artificial intelligence and predictive modeling are deployed to optimize decision making and the actual recycling process. Another leg of the stool is logistics and it involves the company initiative for new plastic waste take-back programs and the facilitation of new supply chains and sourcing.

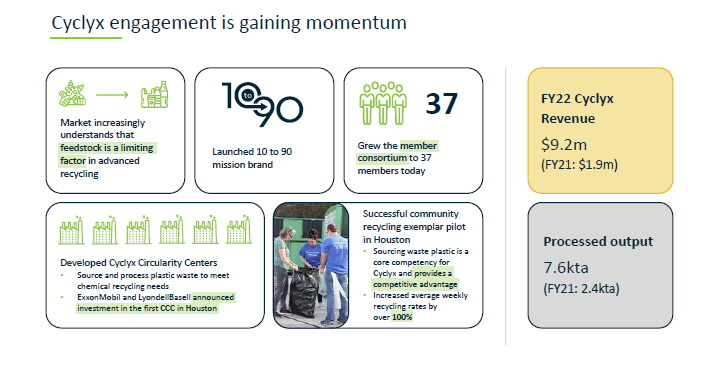

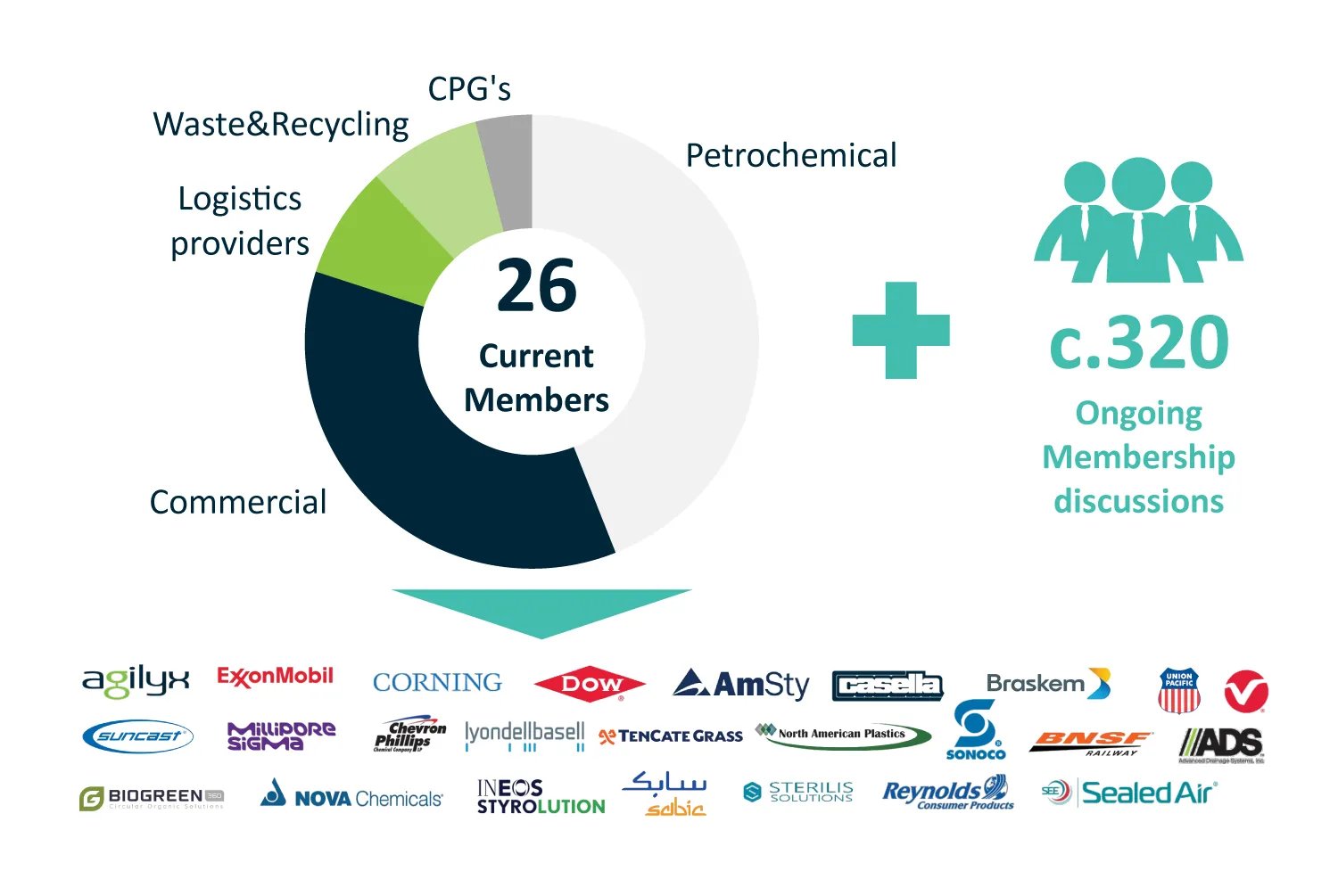

Also, Cyclyx utilizes a consortium approach whereas stakeholders along the value chain (recycling partners, technology partners, suppliers of plastics waste, waste management companies, municipalities and/or regulatory agencies, global CPG or key brand owners) sign up to become members. While these stakeholders may not initially have direct financial interests beneficial to Cyclyx and Agilyx directly or indirectly, they may in the future and the size and growth of the membership base is a good proxy for interest in chemical recycling and robustness of the ecosystem over time.

Quite notably, Cyclyx, ExxonMobil and LyondellBasell recently announced they have signed an agreement to

further advance development of a Cyclyx Circularity Center, a first-of-its-kind plastic waste sorting and processing facility in the Houston area. The new facility addresses a critical missing link in the plastic waste supply chain by connecting community recycling programs to new and more advanced recycling technologies that have the potential to take a much wider variety of plastic materials.

Feedstock to Product Conversion

Source: Company data.

Notes: (1) Represents high priority projects. (2) Includes other pathways.

Agilyx’s part of the process is where the sourced, selected and prepared feedstock from Cyclyx is converted into end products. The actual process is known as pyrolysis and there are many benefits; as no catalyst is required in the process, a broad range of feedstocks, including contaminated ones can be used. Also, the electrified reactor that is deployed in the conversion process can reduce carbon impact. The above diagram illustrates the feedstock types, the current technology and engineering partners and selected customers by types.

Mixed plastic waste is one of the most difficult plastics to recycle. but the opportunity is massive.

There is also a sizable market for styrene/polystyrene.

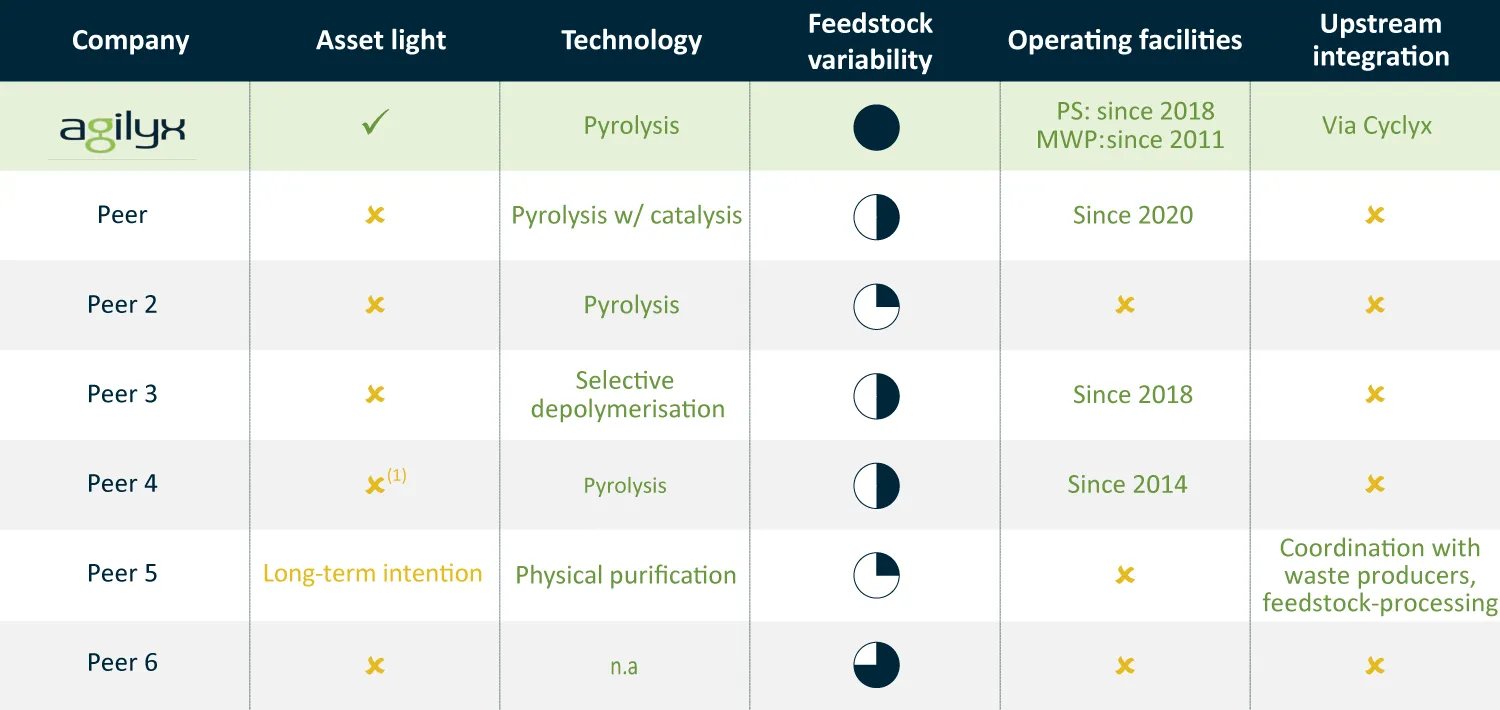

Sizing up Agilyx to its competitors, it wins in all criterias including the asset light attribute from a risk perspective, technology, feedstock flexibility, and upstream (waste-to-feedstock enablement) integration.

Technology is Patented, Proven and Commercially Validated

Patent Summary

-

System for recycling plastics

-

Systems and methods for recycling plastics

-

Systems and methods for recycling plastic

-

Devices, systems and methods for recycling plastic

-

Devices, systems and methods for recycling plastic

-

Methods for recycling plastics and treating pyrolysis vapors

-

Methods for conditioning synthetic cruide oil from pyrolysis

-

Methods and systems for conditioning synthetic crude oil

-

Methods and systems for conditioning synthetic crude oil

-

Methods and systems for conditioning synthetic crude oil

-

Methods and systems for conditioning synthetic crude oil

-

Systems and methods for recycling waste plastics, including polystyrene

-

Systems and methods for recycling waste plastics, including polystyrene

-

Systems and methods for recycling waste plastics, including polystyrene

-

Systems and methods for recycling plastic

-

Systems and methods for recycling plastic

-

Systems and methods for conditioning synthetic crude oil

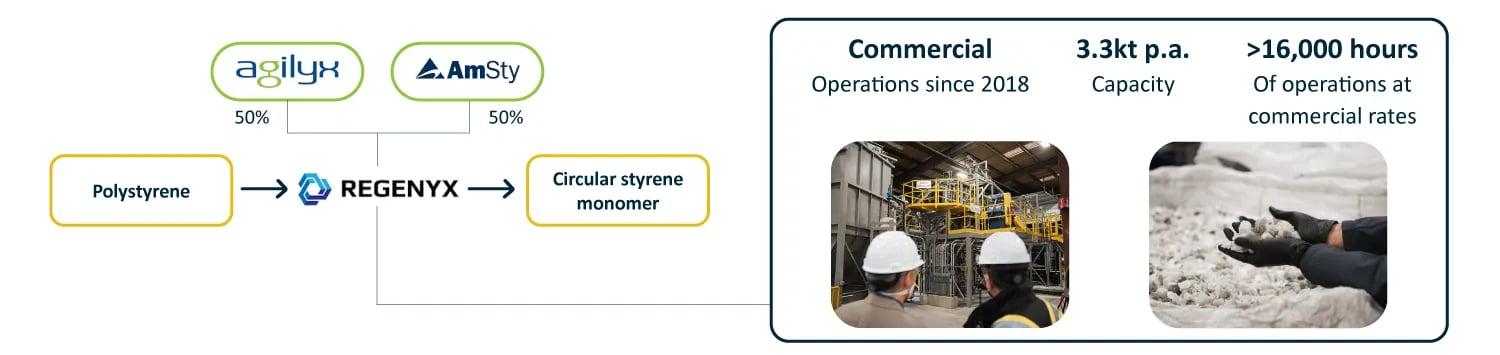

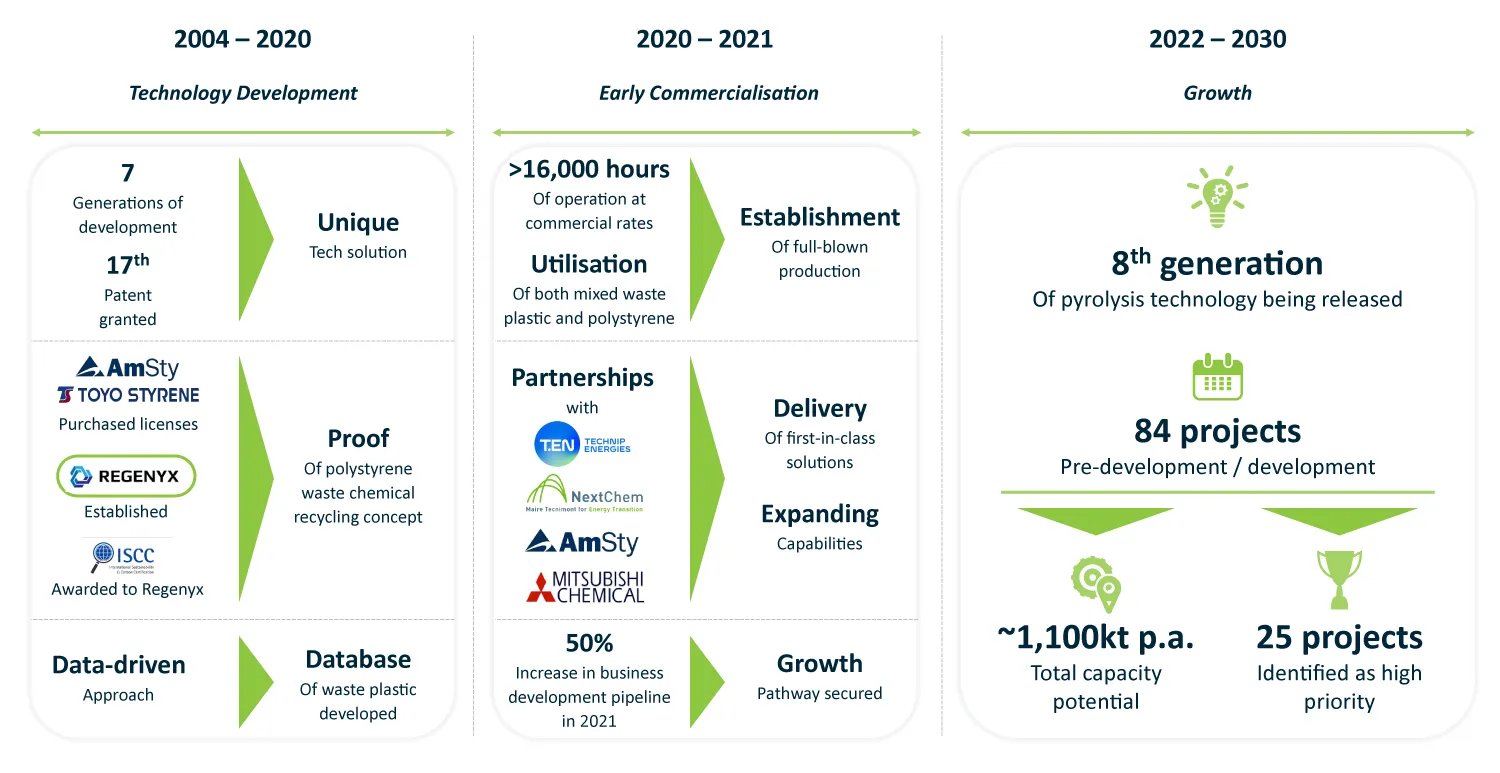

The company owns 17 technology patents as of 12/27/2022and launched the first commercial closed loop plastic-to-plastic facility (Regenyx) in 2018.

Toyo Styrene facility is a first pure licensed polystyrene plant and is currently beginning the construction process now.

A Robust Member, Partner & Investor Base - a Future Growth Anchor

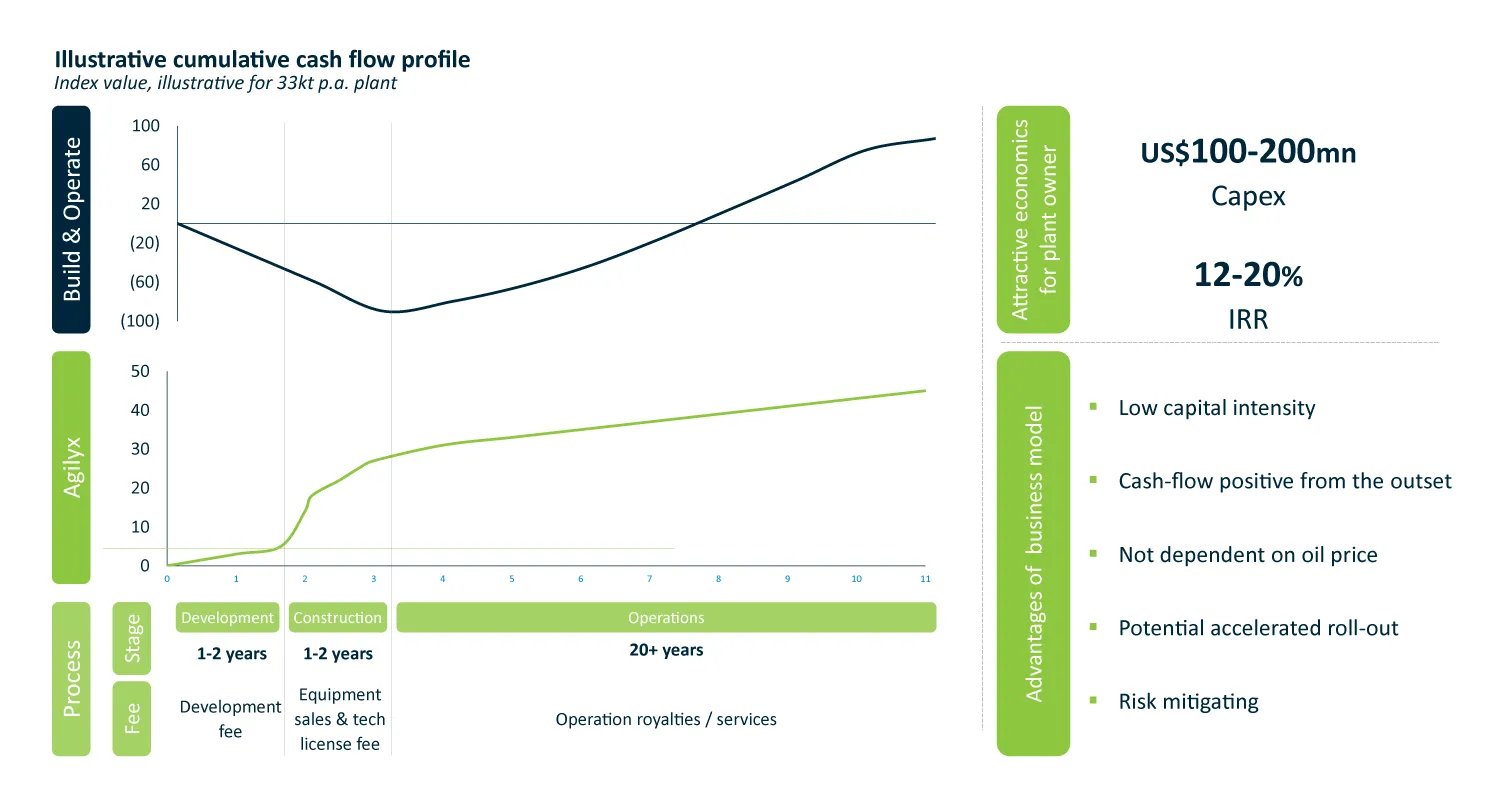

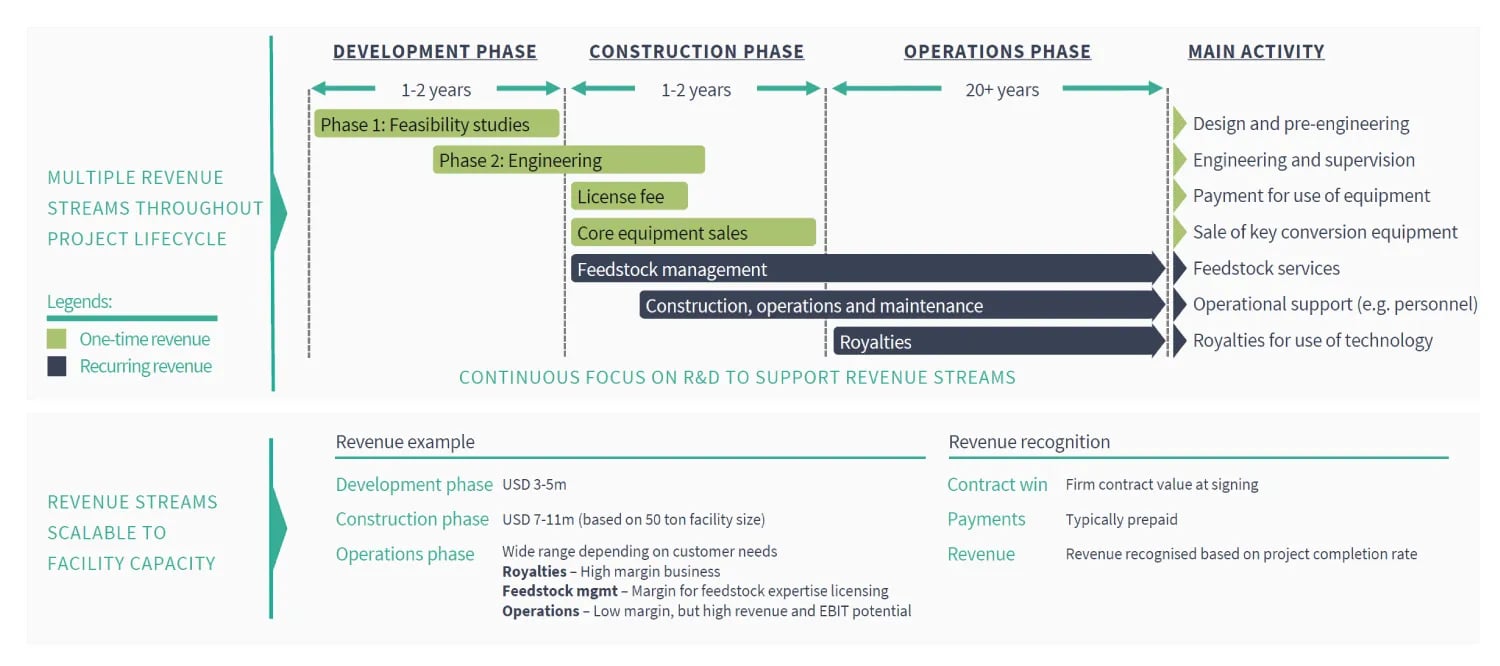

Deploying An Asset Light Model that is Ready To Scale

Agilyx does not own or operate plants other than it’s Tigard plant, rather, it licenses technology to enable the recycling process of these plants and generate licensing revenue based on plant capacity and royalty revenue based on volume of feedstock processed in those plants.

These are the key revenue drivers and recurring revenue streams for the company*. The asset light model enables faster scaling as it requires substantially less upfront capital investment by Agilyx, and it also significantly reduces cash flow risks from the get go and commodity pricing risks (this becomes a greater risk as the industry matures years down the road).

*Note that it also generates other one-time revenue such as fees for feasibility studies and equipment sales.

Rapid Growth to 2030

For thefirst nine months of 2022, revenue was $12.7 million, expanded from $1.4 million in the same period in 2021. With the current project pipeline and growth prospects, the company has a 1,100kt per year recycling capacity potential and 6,000kt per year feedstock volume potential by 2030, both are key drivers for revenue growth for the next eight years.

Current pipeline

1,100 kt pa in total capacity potential by 2030

6,000+ kt pa feedstock volume potential by 2030

Risks & Disclosures

This communication is neither an offer to sell nor a solicitation of an offer to buy, nor a recommendation of any securities of the company mentioned herein.

Agilyx (the “Company”) has reviewed the content of this page as well as the accompanying presentation (“Company Presentation”) displayed on this page. To the best of its knowledge, the Company does not believe this content to be misleading or inaccurate in any material respect, nor does it believe there are any material omissions with respect to such content. The Company does not believe the contents of the page or the Company Presentation to contain any non-public material information.

Information and opinions presented in the Company Presentation are provided by the Company, and makes no representation as to their accuracy or completeness. The information contained on this page is not intended to constitute any form of advice, and the information provided is not intended to provide a sufficient basis on which to make an investment decision. It is not investment research, nor does it constitute a research recommendation, as it does not constitute substantive research or analysis. This information is not to be relied upon in substitution for the exercise of independent judgment.

Information, opinions and estimates contained on this page or in the Company Presentation reflect judgments by the Company as of the original date of publication by the Company and are subject to change without notice. Past performance should not be taken as an indication or guarantee of future performance, and no representation or warranty, express or implied is made regarding future performance.

A complete description of the risks and uncertainties relating to the Company and its securities can be found in the company's filings with the U.S. Securities and Exchange Commission available for free at www.sec.gov.

Information on this page may relate to penny stocks, which may also be referred to as low-priced stocks. Penny stocks are low-priced shares typically issued by small companies. Penny stocks involve greater than normal risk, they may be less liquid than other stocks (i.e., more difficult to sell), and there may be less reliable information available regarding such stocks. Investors in penny stocks should be prepared for the possibility that they may lose their entire investment.

b2i digital or its related entities may own securities of the Company.

The Company is a client of b2i Digital. The Company agreed to pay b2i Digital no greater than $100,000 in cash for 12 months of digital marketing consulting and investor awareness services.

This communication includes forward-looking statements that involve risks, uncertainties and assumptions that are difficult to predict. Words and expressions reflecting optimism, satisfaction or disappointment with current prospects, as well as words such as “believes,” “hopes,” “intends,” “estimates,” “expects,” “projects,” “plans,” “anticipates” and variations thereof, or the use of future tense, identify forward-looking statements, but their absence does not mean that a statement is not forward-looking. The Company’s forward-looking statements are not guarantees of performance, and actual results could vary materially from those contained in or expressed by such statements due to risks, uncertainties and other factors. The Company urges readers to consider specifically the various risk factors identified in its most recent Form 10-K, and any risk factors or cautionary statements included in any subsequent Form 10-Q or Form 8-K, filed with the SEC. Readers are cautioned not to place undue reliance on these forward-looking statements, which speak only as of the date of this communion. Except as required by law, the Company does not undertake any responsibility to update any forward-looking statements to take into account events or circumstances that occur after the date of this communication.

The Agilyx's management and investor relations team is available to talk to current and potential investors. They're happy to answer your questions and tell you what makes their story unique. Please fill out this form, and we will connect you shortly.

• Directly hear the Agilyx story

• Ask your questions

• Submit the form below and someone will get in touch with you as soon as possible

Note: Company management or its representative can only discuss and disclose information that is already available in the public domain. They will do their best to clarify such information to the extent permitted by securities law and industry regulations.

Solving the Global Challenge of Plastic Waste

Tightening regulation is favoring recycling of plastic waste. Agilyx chemical recycling technology provides the solution to the problem.